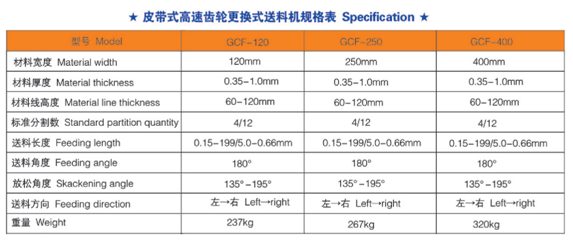

Belt Type High Speed Gear Replacement Feeder

...

Tel

Tel

Belt Type High Speed Gear Replacement Feeder

Features of this machine:

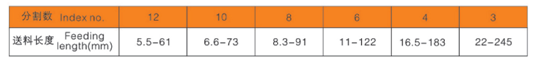

1. It is suitable for punching products with high-speed processing requirements and high-precision feeding. The change of the feeding length is made by the transformation of 1-4 gears.

2. For materials with different thicknesses, variable feeding distances, and large changes in the width of the materials to be sent, the feeding devices of Qingdao Yituo belt-type high-speed gear replacement feeders have a wide range of adaptations.

3. The application is more flexible and convenient. This type of feeder does not need to adjust the feeding thickness, and the feeding distance can be perfectly realized only by gear change.

4. The standard specification (or design) is

explained as follows:

(1) The feeding method of this model is realized by the intermittent use of gears.

(2) When the feed distance is changed, it is formed by the transformation of 2-4 gears, which is flexible and fast.

(3) Only the lower roller is driven and the upper roller is pressed by the spring, and the performance is stable.

(4) When the material is inserted during the feeding process, the upper and lower rollers of the feeder can be loosened by the manual switch of the air valve, and the design is more user-friendly.

(5) Lubrication method--The cam part of the divider is of the oil trough type, while the other gear parts are of the oil immersed type.

(6) The upper and lower rollers are treated with hard chrome plating.

(7) The loosening device of the belt-type high-speed gear feeder is an eccentric cam, so its loosening angle range is large, and it can be adjusted freely between 0° and 180°.

Standard configuration:

1. Material lubrication device. (with flow adjustment)

2. 4 gears. (The number of teeth specified by the customer)

3. Pneumatic material clamping and releasing device

Tel

WeChat scan