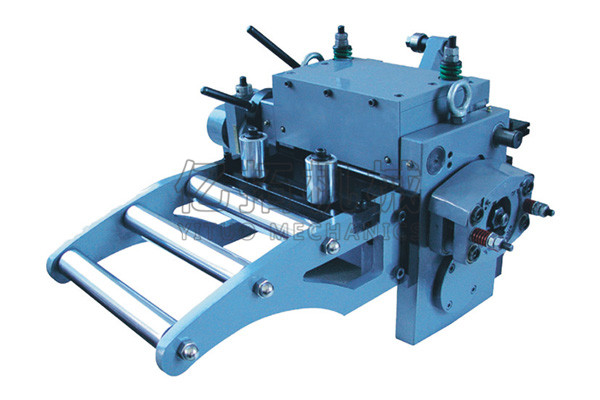

High Speed Roller Feeder

...

Tel

Tel

High Speed Roller Feeder

Features of this machine:

1. The one-way bearing is embedded with superhard alloy and matched with roller bearing, which has wear resistance, safety, high precision and long service life. The gears are heat treated at HR60°C and then precision ground/high transmission accuracy.

2. The roller adopts hollow type, light weight, small rotational inertia, and can be stopped immediately to ensure the feeding accuracy. After heat treatment HR60°C hard chrome regrinding, high hardness, excellent wear resistance and long life.

3. The disc brake (general brake device) adopts advanced clutch to make the two sides fully contact, with long life, good stability and high precision.

4. Reverse device

(1) The structure is the same as that of the one-way device, which can control the lower wheel quite accurately, and the lower wheel will not have the slightest reversal phenomenon when used for a long time, and the stability and precision are quite high.

(2) It will not cause the next wheel to reverse due to the residual oil splashed during stamping, and the brake failure will cause the inaccurate feeding distance.

(3) It is not easy to generate high heat.

(4) With super hard alloy and rollers, it is not easy to wear.

(5) The action mode is that the rollers move in a circular motion, rather than a linear motion such as four guide posts, so there will be no seizure phenomenon.

(6) The friction force is small, the required torsional power is relatively reduced, and the rotating mechanism is less likely to be damaged.

(7) When the reverse device is equipped, the speed can reach 30 m/min, - generally 20 m/min, increasing the efficiency by 50%.

(8) The special structure increases the service life.

Tel

WeChat scan