PNC Servo Feeder Machine

...

Tel

Tel

JNC Servo Feeder Machine

Features introduction:

Application range: Yituo left and right yaw servo feeder production line: suitable for motor punching, aluminum metal stamping parts, small home appliance stamping parts, stainless steel products, lighting products, auto parts and other related wafer stamping industries.

Performance description:

Yituo left and right yaw servo feeder production line has the functions of high-efficiency wafer punching, material saving and high utilization rate. , is an indispensable high-efficiency automatic production line for metal sheet processing wafer blanking. It can be added to an automatic stacking system behind the unit, which can collect punched wafers into stacks.

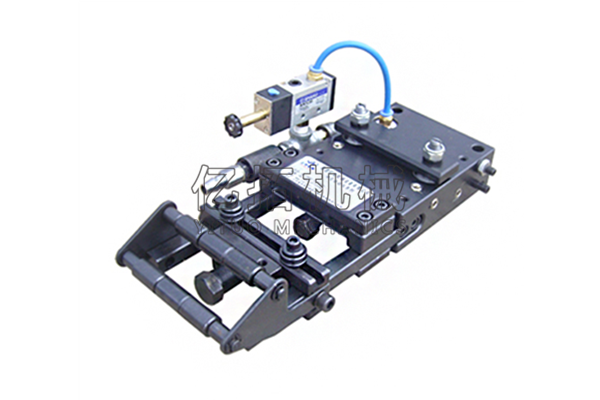

Features of the yaw feeder:

1. The Yituo yaw servo feeder uses an integrated system (generally large machine tools use an integrated system) with more stable performance and convenient operation (generally PLC control system in the market)

2. The yaw and round punching saves Maximum material utilization, tape and reel stamping reduces material costs and achieves greater efficiency.

3. Pneumatic relaxation is adopted (relaxation point is accurate), which can be used for a long time without failure;

4. It is driven by high-quality, brushless servo motor, which can effectively shorten the time for distance adjustment and testing;

5. Use high-sensitivity decoders , The feedback is accurate, and the feeding accuracy is further improved;

6. The motor built-in device can avoid damage during handling and loading and unloading. Structure description:

Composition:

feeding trolley, hydraulic uncoiler, straightening machine (required for materials larger than 1.0MM), left and right shift feeder, high-performance press (customer can choose), punching machine (customer can choose) ), finished conveyor belt (customers can choose), stacking table (optional), other customization, please consult the company's technical staff.

|

number |

production line |

Be applicable |

Material |

Material |

Material |

Material |

Material |

feed |

Yaw |

speed |

total power |

mechanical |

|

1 |

Swing feeder production line |

cold |

1300 |

0.3-1.5 |

450-530 |

1500 |

8-10 |

200±0.25 |

200±0.5 |

Φ200 50times/min |

26 |

10×7 |

|

2 |

1000 |

0.3-1.5 |

450-530 |

1500 |

8-10 |

200±0.25 |

200±0.5 |

Φ200 50times/min |

30 |

13×7 |

||

|

3 |

1300 |

0.3-1.5 |

450-530 |

1500 |

8-10 |

200±0.25 |

200±0.5 |

Φ200 50times/min |

45 |

13×7.3 |

||

|

4 |

1600 |

0.3-1.5 |

450-530 |

1500 |

8-10 |

200±0.25 |

200±0.5 |

Φ200 50times/min |

50 |

13×7.6 |

...

The machine features 1. Suitable for ... ...

...

...

Tel

WeChat scan